Digital twin technology is one of the most disruptive new tools in the world of digital transformation.

Whether it’s powering smart cities or making the development of everything from smartphones to wind turbines more efficient, the technology provides insights that can change how technology – and enterprises – work for the better.

According to a recent survey by MarketsandMarkets, the global digital twin market size in terms of revenue was estimated to be worth USD 10.1 billion in 2023 and is poised to reach USD 110.1 billion by 2028, growing at a CAGR of 61.3% from 2023 to 2028.

Powering this digital twin revolution are a number of key digital twin software solutions which provide a platform for enterprises big and small to embrace this powerful technology.

What is a digital twin?

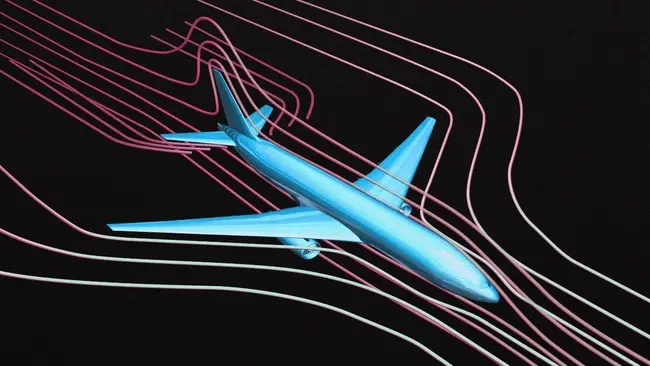

A digital twin is a virtual replica of a real-world thing. This can be a physical object, like a jet engine or a building, or even a process, like manufacturing or traffic flow in a city.

The key is that the digital twin is constantly updated with real-time data from sensors on the physical thing it represents and uses simulation, machine learning and reasoning to help make decisions. This allows the digital twin to mimic the behaviour of the real thing very closely.

The first well-known implementation of a "digital twin" concept was introduced in a roadmap report by NASA's John Vicker to create simulations of spacecraft and capsules for testing.

In order to create and update a digital twin, you need a lot of data. This data can come from sensors on the physical object, from design documents, or from other sources. The studied object—for example, a wind turbine—is outfitted with various sensors related to vital areas of functionality.

These sensors produce data about different aspects of the physical object’s performance, such as energy output, temperature, weather conditions and more. The processing system receives this information and actively applies it to the digital copy.

After being provided with data, the digital model can be used to conduct various simulations, analyze performance problems and create potential enhancements. The ultimate objective of this is to obtain crucial information about the object of a system that can be used to improve the original physical entity.

What is digital twin software?

Digital twin software is essentially a toolbox for creating and managing virtual replicas, the digital twins, of real-world things. These programs provide the environment to build the digital twin, connect it to real-time data sources, and analyze the data to understand how the physical counterpart is performing.

This allows you to create a digital representation of the physical object or system through 3D modelling, incorporating engineering data, and connecting to sensor inputs. Digital twin software can connect to sensors and other data sources to collect real-time data about the physical object. This data is then used to update the digital twin and keep it accurate.

The software also provides tools for analysing the data collected from the physical object. This can be used to identify trends, predict problems, and optimize performance.

AI Reshapes Manufacturing Design

Manufacturers are shifting from static CAD to AI-led, lifecycle-aware design using ML, DL, NLP and vision to cut cost and accelerate innovation.

Why is digital twin software important?

Digital twin software unlocks the benefits of digital twin technology by streamlining the process and making it more accessible. Without digital twin software, creating and maintaining these complex virtual replicas would be a much more difficult and time-consuming process. The software provides user-friendly tools to streamline development and ongoing management.

Through real-time data integration, the software acts as a bridge between the physical world and the digital twin. It facilitates the seamless flow of real-time data from sensors and other sources, keeping the digital twin constantly updated and reflecting the actual state of its physical counterpart.

Digital twin software goes beyond just integrating and visualizing data too. It offers powerful analytics tools that allow users to identify trends, predict potential problems, and optimize performance based on the data collected from the physical system.

With real-time data and insights, businesses can make more informed decisions about everything from maintenance schedules to product design. At the same time, digital twin software’s predictive capabilities can help prevent costly breakdowns and optimize resource allocation, leading to significant cost savings.

By identifying bottlenecks and optimizing processes through digital twin simulations, businesses can achieve greater efficiency in their operations

In essence, digital twin software acts as the bridge between the physical world and the digital world of data. It simplifies the creation and management of digital twins, unlocking the valuable insights they offer for improved decision-making, performance optimization, and innovation.

Inside Industrial IoT Stacks

Explore how IoT, edge compute, satellite links and eSIM are being assembled into scalable architectures showcased at Olympia London.

Benefits of Digital Twin software

Digital twin technology offers a range of advantages that can transform how businesses design, operate, and maintain physical assets. These include:

1. Enhanced decision-making

Imagine being able to simulate different scenarios before implementing changes in the real world. Digital twins allow you to do exactly that. By creating a virtual model, you can test different operating conditions, maintenance strategies, or product designs to see how they would impact performance. This empowers businesses to make data-driven decisions that optimize efficiency and minimize risks.

2. Reduced costs

Digital twins can help identify and prevent problems before they occur. By monitoring the digital replica and analyzing sensor data, you can predict potential equipment failures or production issues. This proactive approach allows for preventive maintenance, reducing the need for costly repairs and downtime.

3. Increased efficiency

Digital twins can be used to streamline processes and improve overall operational efficiency. By analyzing data from the digital model, businesses can identify bottlenecks, optimize resource allocation, and adjust processes for better performance.

When Automation Reshapes Talent

Assess the organisational risks, skills gaps and cultural tensions as human–AI collaboration, chatbots and automation accelerate across knowledge work.

4. Improved product development

In the design phase, digital twins can be used to virtually test and refine products before physical prototypes are built. This reduces development time and costs, while also ensuring the final product meets performance expectations.

5. Boosted innovation

Digital twin technology opens doors to new possibilities. Businesses can use digital twins to explore innovative concepts, test new technologies, and optimize complex systems in a virtual environment. This fosters a culture of innovation and helps businesses stay ahead of the curve.

These are just some of the key benefits of digital twin technology. As the technology continues to evolve, we can expect to see even more innovative applications emerge across various industries.

Best Digital Twin Software Solutions

Choosing the best digital twin software for your business depends on your specific needs and industry. Here are ten of the top digital twin software solutions on the market in 2024 based on their popularity, user reviews, and range of features.

Comments ( 0 )